PolyMod® Advantage

Low-Friction, High-Performance Sealing

Seal friction can negatively affect system performance, efficiency, and life. PolyMod® high performance thermoset and thermoplastic rubber materials are polymer modified to have very low coefficients of friction and optimized wear life giving them significant advantages over conventional elastomer seal materials.

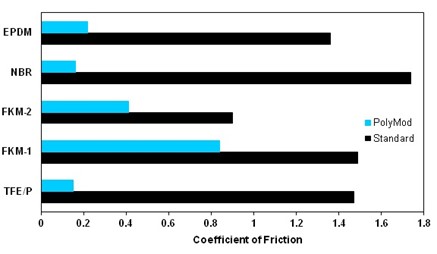

Breakout Friction Values

High Performance Materials vs. Standard Materials

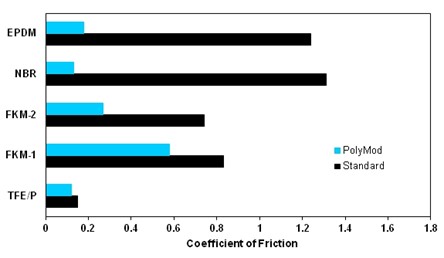

Running Friction Values

High Performance Materials vs. Standard Materials

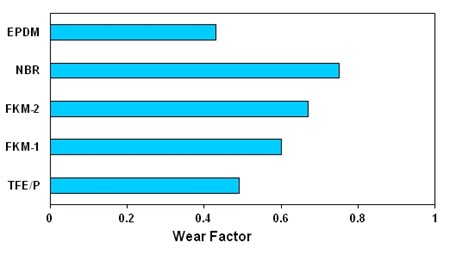

Reduced Abrasive Wear

Even in hydraulic systems, seal materials are worn and abraded. PolyMod® materials significantly show improvement in wear life over conventional elastomer.

Graph Notes

- Evaluations using Taber Abrasion (ASTM D3389)

- H-18 wheels at 1 kg loading

- Values are the mean of the three separate runs taken

- The wear of the PolyMod® materials is shown as a factor less than 1.0, indicating improved wear resistance when compared to the standard materials

No Adverse Material Property Changes

PolyMod® does not change physical properties. The PolyMod® process can be performed on O-rings to custom shapes and from seals to other rubber parts.

AS568-214 NBR O-Rings - Original Physical Properties

| Physical Property | Standard NBR Material | PolyMod® High Performance Material |

|---|---|---|

| Tensile Strength (psi) | 2230 | 2158 |

| Elongation (%) | 290 | 287 |

| 100% Modulus | 551 | 556 |

| Hardness (Shore A) | 71 | 71 |

| TR10 (°F) | -24 | -27 |

AS568-214 NBR O-Rings - Physical Properties After Aging

70 hours @ 302°F in ASTM #3 Oil

Physical Property | Standard NBR Material | PolyMod® High Performance Material |

|---|---|---|

| Tensile Strength Change (%) | -52 | -37 |

| Elongation Change (%) | -38 | -28 |

| Hardness Change (pts.) | 7 | 7 |

| Volume Swell (%) | 16 | 16 |